3 Process Change Lessons From a Rescue Dog

What can you learn from a dog?

One day I returned from a business trip to learn that we would be adopting a new rescue dog. Evidently our current dog was lonely and somehow convinced my wife that he wanted a brother.

Enter Logan – a three pound Maltese mix who had been mistreated and left out in the woods to die. He was a survivor though and somehow made it to an animal care center. He was diseased, underweight, scared, and didn’t trust humans. In fact he didn’t even know how to play. Today he’s up to a healthy 9 lbs. and happy (most of the time). Along his journey he demonstrated some great lessons in change from which we can all benefit as we wrap up our year.

Lesson 1: The Dust Will Eventually Settle on Any Change When Logan first came to live with us he promptly went under the couch and pretty much said “if anybody needs me, I’ll be under here for the foreseeable future”. This was a lot of change to absorb for the little guy so he immediately retreated to the dark cave of safety. Was this a positive change for him? Yes – on many levels. However, he needed time to assimilate that change. Ultimately he came out and learned all the great aspects of his new life. Nowadays, he’s only under the couch during loud storms – where I feel like joining him. RX: Whenever you roll out a process change of any significance that impacts people – be it positively or negatively – they need time to absorb the change and become acclimated to the new way. Know that some of them will shoot under the couch and all you’ll see is their eyes glowing in the dark. Getting them involved early on in the design allows them to become acclimated much faster once the rollout period hits.

Lesson 2: Crisis or Opportunity? It’s All About Perspective Our original dog Leo views humans as a giant source of snacks and belly rubs while Logan sees any human as a would-be assassin. When you go to roll out a process change – one person impacted by it may see it as great while the person in the office next to them thinks it’s the worst thing they’ve ever seen. Whether or not someone resists your proposed process change is a function of their filter or perspective on things. We can help adjust that filter and get better change adoption, but first we need to know about it. RX: As you are designing your change, get input from the people who will be impacted. Make it safe and easy for them to either wag their tails or growl at you (metaphorically speaking…).

Lesson 3: Don’t Let the Shiny Objects Distract You Both of our dogs get excited when they see something super-interesting like a squirrel, butterfly or leaf. They are on sensory overload, their attention flitting from thing to thing until they find a scent they like at which point their focus locks in better than a heart surgeon doing a bypass. Dwayne Johnson and Arnold Schwarzenegger combined couldn’t move that 9 pounder from the tree some other dog recently marked. As you roll out your process change it helps to keep in mind that the volume, speed, and complexity of information coming at us today is greater than any other point in history. Your finely crafted email announcing your upcoming change is just one of 147 other communications hitting your audience that morning – it gets lost in the whitewater of visual and auditory inputs washing over us every nano-second. RX: Have a communication plan for your change, start it early in the process, and be prepared to communicate multiple times and in multiple ways.

Now, if you’ll excuse me, there is something evidently of international importance going on in my den regarding a chew toy. Happy change.

Brought to you be Jeff Cole – helping people improve results through creative process improvements.

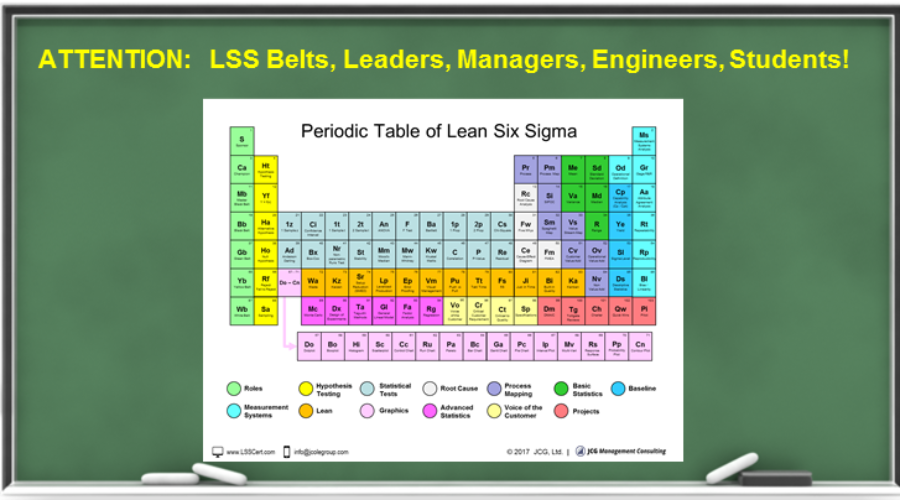

The Periodic Table of Lean Six Sigma

New Infograph on Lean Six Sigma

Do you reference the Periodic Table a lot? When I was in business school we referred to the Periodic Table of Elements exactly zero times. Thus, I sadly can’t tell you the difference between Boron and Chromium.

The table is however, a clever way of organizing things into different categories — for those of us who are not scientists. After seeing several examples using the table in different contexts (Periodic Table of Music Groups, Periodic Table of Game Controllers, etc.), I decided to create one for Lean Six Sigma.

Is this comprehensive? Absolutely not, but it will hit a lot of your favorite topics, tools, and techniques.

You can tour it on this short video and then download a free, full-size color PDF here. You can also get the interactive version here – where you can click on any element to learn more about it and see examples. It’s a fun way to refresh your memory, review, or test your knowledge.

A special tip of the hat to Diana Davis of the Process Excellence Network who published a nice table for process excellence a while back and to all the others whose creative alternative uses for the table served as inspiration.

Brought to you be Jeff Cole – helping people improve results through creative process improvements.

Using the Project Tree for Proper Project Selection

Seen a few project “train wrecks” in your day? If so, you’ll understand this: Success begins with project selection and choosing the right tool for the right job.

If you wanted to nail two pieces of wood together you could absolutely do so with a wrench if you were persistent enough! A hammer would have been a much better choice. With that in mind, let’s look at how to choose the right method among six of the most popular improvement approaches available Check out this short video to see why.

4 Steps to Selling Your Process Change Now!

“Secret” Madison Avenue Process reveals how to sell your next idea in 4 easy steps!

Imagine this – you work super hard on a process improvement but people aren’t using it like they should. Sound possible? The remedy may lie in a “secret” method used by the high-priced advertising geniuses from Madison Ave.

Hands-down, these guys are the masters of behavioral change. Case in point – they are said to have doubled mid-century shampoo sales by simply putting “rinse, repeat” on the bottles.

Today, advertising involves vacuuming up the massive digital breadcrumbs people leave behind on every click, scan and keystroke, and crunching through mind-numbing algorithms to determine which ads to spew forth on your screen next. Yet, underlying all that tech is still the old-school formula that you can leverage on your next process change.

The secret formula? AIDA – Awareness, Interest, Desire, Action. If you want somebody to buy into your change, first make them aware of it, get them interested, and make them desire it to the point they take the action of “purchasing” it. How would that help you on a typical process improvement project?

Awareness: Starting in the planning stages you should be developing a communications plan that you execute through all the improvement steps. Do not wait until the end to “advertise” your project. People need to be exposed to your change multiple times before they really become aware of it.

Interest: When you build the business case for your project, be sure to articulate your Vision (What’s in it for the user) and your Burning Platform (Bad things that happen if you don’t implement the change now). Use both of these in your communications to spark interest among your target audience.

Desire: Most purchasing decisions are said to be driven by emotion, even though we justify those decisions using logic. Granted, it’s hard to inject emotion into a new invoicing process. But, if your new process will relieve pain that people are feeling, it’s easier to leverage that. Excitement is an emotion. At a minimum, ensure that all the people executing your communications exhibit the proper excitement. All else being equal, consumers tend to buy from people they like. Leverage that in terms of who you have doing the communicating for your project.

Action: Ask for the sale – this is your version of the “Buy Now” button. Ask your audience to engage in the new process – preferably in a non-threatening way. This may take the form of training, seeing a demo, participating in a pilot, attending a kickoff, etc. Even a micro-commitment such as signing a pledge or making an appointment to view a training video gets them started. Make it as easy as possible for people to follow the new process. (Simultaneously, make it hard for resistors to try to do things the old way.)

All told, everyone would be well served to realize that we are all in marketing, advertising, and sales regardless of our title. Happy selling!

Why Lean Six Sigma is Pokémon Go for Business

Hard to get through 2016 with hearing about the latest viral game app – Pokémon Go. Much easier to go through your year without hearing about Lean Six Sigma. It’s doesn’t tend to pop up on the nightly news or People magazine. However, at its core the two are similar and Pokémon Go serves as a nice metaphor for Lean Six Sigma. Check out this short video to see why.

Why Not 99.9% Quality?

What was a grade of an “A” where you went to school?

For many people that answer is 90 – 100%. Since childhood, we’ve been conditioned to believe that 90% or above is quality work. You report for duty at your first job and think “if I do 90% on this, my boss will certainly track me down and give me an A”. Unfortunately, while 90% quality is excellent in some areas (You may wish 90% of your flights arrived on time) it’s unacceptable in other areas (your dentist says there’s a 90% chance he’s about to drill in the correct tooth).

Some processes and products require screaming-high quality levels. The next time you think about quality, consider this.

If 99.9% quality were good enough, then:

• 400 words in Webster’s Dictionary would be misspelled

• Doctors would give 12 babies to the wrong parents each day

• There would be 730 unsafe landings at O’Hare airport annually

• 500 incorrect surgical procedures would be performed each day

• 2,488,200 magazines would be published with the wrong covers

• 2,000,000 documents would be lost by the IRS in a year

(source: industryweek.com)

5 Proven Tips for Successful Process Change

Managing the human side of process improvement is often key to the success of any Lean, Six Sigma, or other process improvement effort (heck, some say it’s 80% of the battle).

Managing the human side of process improvement is often key to the success of any Lean, Six Sigma, or other process improvement effort (heck, some say it’s 80% of the battle).

You can create the best process in the world, but if the people who must engage in that process don’t do so, you might as just toss all your time and money out the window.

Here are five “street smart” tactics you aren’t likely to find in the textbooks. Each is covered by a short video in separate blog posts below. You can also read my article about all 5 tips right here.

1. Understand the need for change management

2. Start early on your change efforts

3. Select a change management method to use

4. Integrate change management into your overall improvement approach

5. Uncover resistance to change so you can manage it

For even more tips on managing change, download one of our free white papers.

And to learn more about the leading method for process improvement, click here.

Brought to you by Jeff Cole – helping people get better results through innovative process improvements.

How to Drive Better Process Change – The “Understand the Need” Tip

Make Your Next Process Improvement a Smashing Success

You can have the best process in the world, but if the people you want to use that process don’t do so, you’ve wasted your time and money.

So, how do we get people who don’t report to us or maybe don’t even know us to change their behaviors and use our process?

Watch this mercifully brief video about how to use the “understand the need” tip to help ensure your next process improvement is a success:

You can check out the entire article with 5 tips to ensure your process improvement success right here.

For even more tips on managing change, download one of our free white papers.

And to learn more about the leading method for process improvement, click here.

Brought to you by Jeff Cole – helping people get better results through innovative process improvements.

How to Drive Better Process Change – The “Start Early” Tip

Make Your Next Process Improvement a Smashing Success

Your best process improvement is totally useless if people don’t use it like they should.

And getting people to use your process isn’t as easy as clicking a button in Excel. So, what can you do to ensure your success?

Watch this mercifully brief video about how to use the “starting early” tip to help ensure your next process improvement is a success:

You can check out the entire article with 5 tips to ensure your process improvement success right here.

For even more tips on managing change, download one of our free white papers.

And to learn more about the leading method for process improvement, click here.

Brought to you by Jeff Cole – helping people get better results through innovative process improvements.

- 1

- 2